Introduction of silica sand purification process. In natural quartz sand ore, due to weathering and sedimentation, a large amount of clay and iron are mixed in and pollute the surface of quartz sand. At present, most of the domestic natural placers are realized by means of strong scrubbing and hydraulic classification. At present, the domestic silica sand scrubbing process mainly includes two methods: rod scrubbing and mechanical scrubbing. Our company uses mechanical scrubbing.

The scrubber is suitable for the process of beneficiation, and the scrubbed materials are beneficial to flotation, mineralization and recollection. At the same time, the scrubbing machine is a high-concentration, powerful stirring scrubbing equipment. It is suitable for metallurgy, chemical industry, building materials, light industry, food, pharmacy and other industries and departments to scrub the surface of materials. The use and maintenance of silica sand slurry scrubber is particularly important.

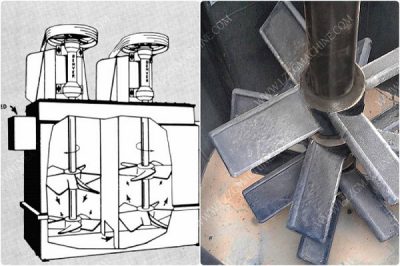

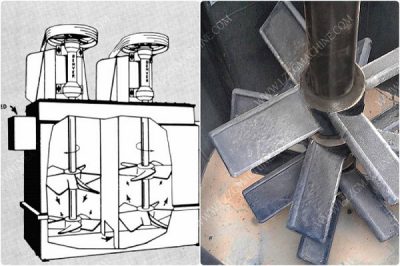

Structure and principle of silica sand slurry scrubbing machine: This machine is a double trough. Each trough of the scrubbing machine is equipped with an independent transmission system. Each trough is driven by a motor through a triangular tape to drive the main shaft to rotate at high speed. Each main shaft is equipped with two high-speed impellers that rotate in opposite directions. , The axial thrust and stirring capacity of the two impellers are not the same. The main shaft has two structural forms, and its installation position is related to the flow direction of the ore flow. The direction of the scrubbing force must be the same as the flow direction of the ore flow.

During the scrubbing process, the mineral liquid of the silica sand slurry scrubber is first strongly pushed by the upper impeller, and then pushed in the opposite direction by the lower impeller, so that the material collides strongly between the two impellers under the action of two opposite thrusts to form friction. The dirt, impurities and oxides attached to the surface of the material are separated from the material, and the fresh surface is exposed, creating conditions for improving the efficiency of the next process. The scrubbing effect also increases with the increase of the slurry concentration, and the actual power consumption also increases.