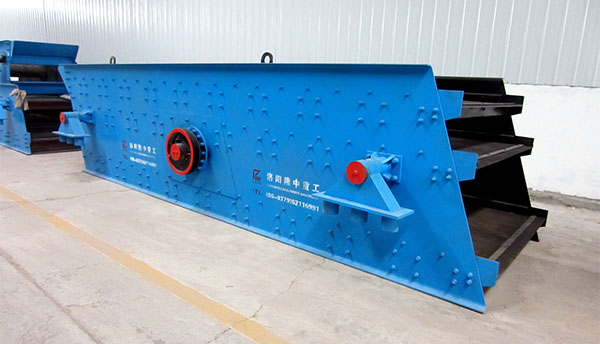

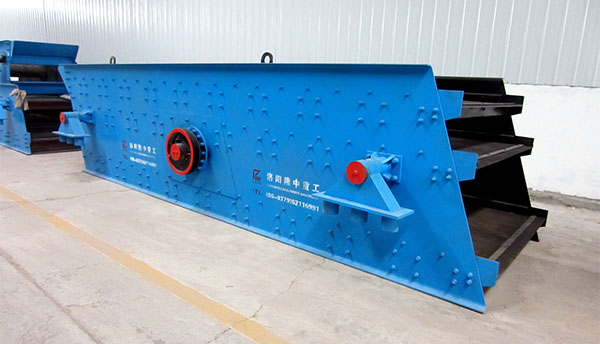

The circular vibrating screen is a screening equipment commonly used for coal, limestone, gravel, gravel, and other materials. Because the moving trajectory of the screen box is round, it is called a circular vibrating screen. It can also be used for double layer screening.

The vibrating screen adopts cross shaft universal joint drive shaft or rubber. Flexible coupling such as coupling, running smoothly, the exciter adopts the block eccentric form, which not only increases the single-excitation force of the exciter eccentric mass, but also the excitation force can be randomly adjusted, which is convenient for modular design and use, and can be changed. The inclination angle of the screen surface changes the movement speed of the material along the screen surface, and the treatment amount of the G sieve, the vibration intensity G, the large production capacity, the screening efficiency G, the maintenance and maintenance are convenient, the service period and the service life of the whole machine are long.

The vibration screen is mainly composed of a screen box, a screen, a vibrator and a vibration-damping spring. The vibrator is mounted on the side plate of the screen box and is rotated by the motor through the coupling to generate centrifugal inertial force, forcing the screen box to vibrate. The YK type eccentric circular vibrating screen is a single mass elastic system, and the electric motor passes through the elastic coupling to make the exciter eccentric mass produce G speed rotation. The running eccentric block generates a large centrifugal force, and the screen box generates a circular motion of D amplitude. The material on the screen is subjected to the impulse of the screen box on the inclined screen surface to generate a continuous throwing motion, and the material meets the screen surface. The grading is achieved by sieving the particles smaller than the mesh in the process.

It has the characteristics of large processing capacity, low maintenance cost and simple installation and use. It is suitable for coal, limestone, gravel, gravel, metal or non-metallic ore. And screening of other materials.