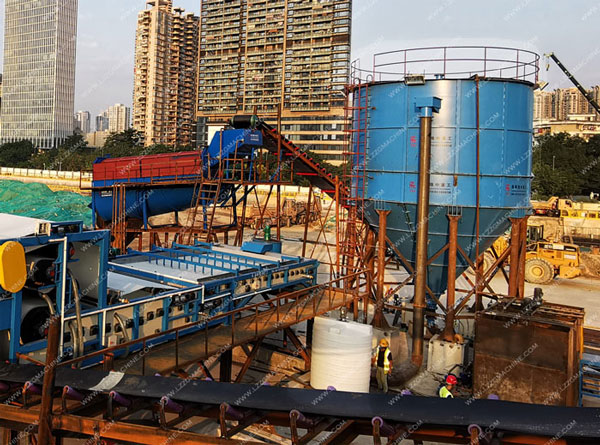

Thickener tank for sand washing wastewater reuse

November.19,2019

November.19,2019

During the process of washing sand and washing coal, a large amount of sewage is generated. The greater the amount of water consumed, the better the washing effect. However, many sand washing plants are very headaches for the waste water generated by sand washing. Waste water tanks, sedimentation tanks and sewage tanks are used for waste water recycling. This not only takes up a lot of space, but the sewage treatment speed is very slow.

The sand washing thickener tank can speed up the mud-water separation efficiency and eliminate the clean water for sand washing. This can save you a lot of water resources. Increase the output of the sand washing machine and reduce the pollution to the environment.

Principle of sewage purification

The deep cone thickener is a solid-liquid separation device based on gravity sedimentation. When working, the solid particles suspended in the slurry in the vertebral body of the concentrator are settled under the action of gravity, and the upper part becomes clarified water, so that the solid liquid can be separated. The slurry wastewater with solid content of 2% to 15% can be lifted by gravity to increase the concentration to 60% to 70% mud, and the upper part of the tank can realize the overflow of water, thereby achieving the purpose of sewage purification and solid-liquid separation.

Advantages of LZZG thickener tank

1. High-efficiency deep cone concentrator Because the cell body is slender, flocculant is added during the concentration process to accelerate the concentration process of material settling and overflow water clarification.

2, using suspension filtration, medium adsorption, precipitation working principle, no purification film, no wearing parts.

3. The tank body is made of high quality carbon steel (or stainless steel, epoxy glass reinforced plastic, etc.) material, which has good strength and corrosion resistance.

4. The use cost of the medicament is low, the treatment amount is large, the treatment efficiency is high, and the performance is stable.

5, small size, small footprint, easy to install.

6. The service life of the whole machine is 10-15 years, with less one-time investment and significant economic benefits.

7. The processing capacity is higher than the traditional thickening machine, and the quality of the overflow water can reach the national emission standard.

Contact us

Tel: +86-379-65160016

Cell: +86-13598484277

Email: export@lylzzg.com