Banana screen working principle and Operation rules

June.20,2019

June.20,2019

What is a banana screen

The banana screen is a vibration screen with a box vibrator and a plurality of different inclined sieves. The shape of the main box is similar to that of a banana. It is mainly used for the classification of large and medium-sized materials with high fine content, and can also be used for dehydration, de-intermediation, and de-sludge operations. (The fine particles refer to particles with a particle size of less than half the size of the mesh.)

The banana screen is designed by injecting a banana-shaped multi-stage working surface on the basis of a linear classifier. There is a larger slope screen at the feed end, followed by a stepwise decrease at a certain number of angles until the discharge opening, the overall screen surface is concave curved. The sloped screen at the feed end allows for more material to pass through the screen surface with higher screening speeds and thinner material delamination.

Because the bulk material passes through the steep slope faster, this earlier stratification allows the fine particles to move closer to the screen surface and pass through the gap relatively unhindered, so the banana sieve has a very high screening efficiency and It is the most advanced and most popular screening machinery product, which is 1.5-2 times higher than traditional grading screen.

Working Principle

The banana vibrating screen has a sloped surface at the feed end, starting with 34° and then descending to a discharge end of about 10° at a certain number of angles. The screen surface is in the form of a fold line with different inclination angles, and the thickness of the material layer from the feed end to the discharge end is constant. The ratio of material volume to flow rate on each screen surface is stable, the material layer is higher, and the screening efficiency is uniform, which is 1-2 times higher than that of the same effective area screening machine.

For high fine content, especially materials The banana vibratory screening machine has a very high screening efficiency when the medium content is larger than the material having a classification size of less than 1/2.

Application

It is used for the screening of sinter, coal, limestone, crushed stone, gravel, metal or non-metallic ores and other materials. It is widely used in metallurgy, coal, building materials, refractory materials and other industries.

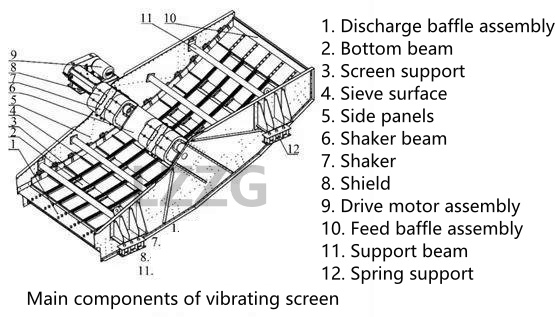

The Shaker of Banana Screen

Advantages And Features

1. Low power consumption, high vibration intensity (9-12mm), high screening efficiency (>95%);

2. The domestic brand patented screen surface configuration is adopted, and the material handling capacity is large;

3, light weight, low working noise, stable operation;

4. The operation and maintenance of the sieve machine is simple, safe to use and cost-effective.

Operation rules

1. Before the sieve is started, all the protective covers should be installed in place and all personnel should be evacuated from the sieve;

2. It is forbidden to start the sieve machine until the various protective covers are not fixed;

3. Do not stand within one meter of the screen machine during the start and stop of the screen machine;

4. When the sieve machine is in operation, do not stand on the vibrating parts;

5. The screen motor must be de-energized and the screen machine stopped before any work can be started on the screen.

Models and Parameter

| Models | sieve layers | Width×Length(m) | Size(m2) | Screen segments |

| JR1848 | 1 | 1.8×4.8 | 8.6 | 4 |

| JR1861 | 1 | 1.8×6.1 | 10.8 | 5 |

| JR2448 | 1 | 2.4×4.8 | 11.5 | 4 |

| JR2461 | 1 | 2.4×6.1 | 14.4 | 5 |

| JR2473 | 1 | 2.4×7..3 | 17.2 | 6 |

| JR2485 | 1 | 2.4×8.5 | 20.1 | 7 |

| JR3061 | 1 | 3.0×6.1 | 18 | 5 |

| JR3073 | 1 | 3.0×7.3 | 21.6 | 6 |

| JR3085 | 1 | 3.0×8.5 | 25.2 | 7 |

| JR3661 | 1 | 3.6×6.1 | 21.6 | 5 |

| JR3673 | 1 | 3.6×7.3 | 25.9 | 6 |

| JR3685 | 1 | 3.6×8.5 | 30.2 | 7 |

| JR4261 | 1 | 4.2×6.1 | 25.2 | 5 |

| JR4273 | 1 | 4.2×7.3 | 30.6 | 6 |

| 2JR1861 | 2 | 1.8×6.1 | 10.8 | 5 |

| 2JR2461 | 2 | 2.4×6.1 | 14.4 | 5 |

| 2JR2473 | 2 | 2.4×7.3 | 17.2 | 6 |

| 2JR3061 | 2 | 3.0×6.1 | 18 | 5 |

| 2JR3073 | 2 | 3.0×7.3 | 21.6 | 6 |

| 2JR3661 | 2 | 3.6×6.1 | 21.6 | 5 |

| 2JR3673 | 2 | 3.6×7.3 | 26 | 5 |