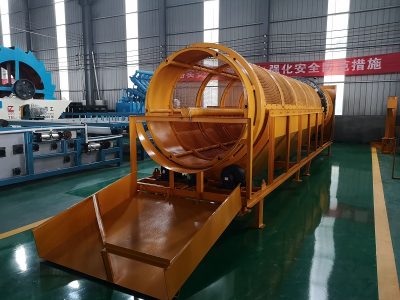

Drum screen remove rock from soil

April.28,2020

April.28,2020

Drum screen applicable industries

The shaftless drum screen is mainly suitable for the classification and desilting of dry and wet materials in the fields of mining, coal, power, garbage, commercial concrete residues, construction, chemical industry, etc., and can also be used for dehydration of coarse particles. With the upgrade of the manufacturing technology of the rotary screen, the manufacturing cost of the drum screen is gradually reduced, and the price is low. It is now widely used in the pre-divided work of the sand gold mine, and can also be used in conjunction with the drum washing machine or trough washing machine. The muddy sand gold with high mud content and relatively high viscosity is used for effective screening and loosening.

Operation method of large shaftless drum screen

1. Choose a suitable site to lay the equipment flat, first confirm that the foundation has sufficient strength (hardened with concrete if necessary) to ensure that the equipment can work normally and safely;

2. Check whether the bolts in each part are loose and whether the operating parts are abnormal; the structure of the multi-function and efficient drum sand screen

3. Turn on the power and check whether the motor and various transmission parts work normally;

4. No-load test run, check the temperature rise of the motor and transmission parts and whether there is abnormal noise;

5. After the test run is normal, you can add the material and observe whether the discharge is normal. When the belt is normal, close the sealed isolation cover, you should first open the belt conveyor, and then open the drum screen. The feed at the inlet should be uniform and not excessive; check the discharge particle size and No leakage or dust.

Movable stone shaftless drum screen sandstone bentonite separation screen pebble filter drum screen is strictly forbidden to start with load, and the material of the conveyor should be unloaded before the shutdown after each shift.