Dimensions of automated plate and frame filter press

October.11,2019

October.11,2019

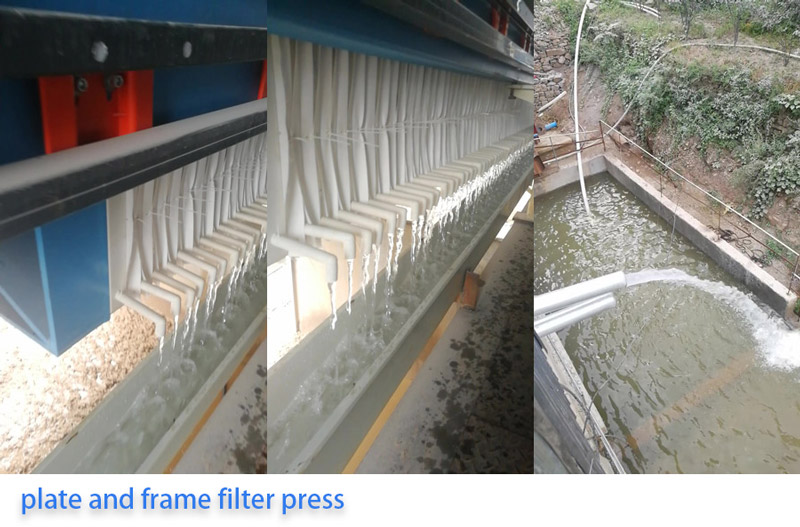

The plate and frame filter press is the first machine used in chemical dehydration. Although the plate and frame filter press generally has intermittent operation, large investment in infrastructure equipment, and low filtration capacity, it has large filtration driving force, high solid content of filter cake, clear filtrate, high solid recovery rate, and conditioning medicine. The advantages of low consumption and so on are still widely used in some small sewage plants.

Automated plate and frame filter presses Vacuum filters can withstand higher sludge specific resistance, which reduces the consumption of conditioning agents and allows the use of less expensive agents (eg FeSO4·7H2O). When the specific resistance of the sludge is 5 × 10 ¹¹ to 8 × 10 ¹² m / kg, it can be directly filtered without pre-conditioning. The mud cake yield and mud cake moisture content of the plate and frame filter press shall be determined based on test data or similar operating experience. The moisture content of the mud cake can generally be 75% to 80%.

Advantages

1. Providing efficient cleaning support to sludge accumulated in wastewater.

2. The machine works on the principle of pressure feeding that provides for optimum output support.

3. Supports a reduction in the moisture content of sludge significantly.

4. Working as the solid-liquid separation device, the system can also be custom-tuned as per the specific work process needs of customers.

5.Suitable for dewatering low and high concentrated sludge.