Recently, customers in Jiangsu Province visited LZZG and signed a cooperation agreement for the granite sand production line project. The production capacity of this production line is 300t/h. The processing material is granite.

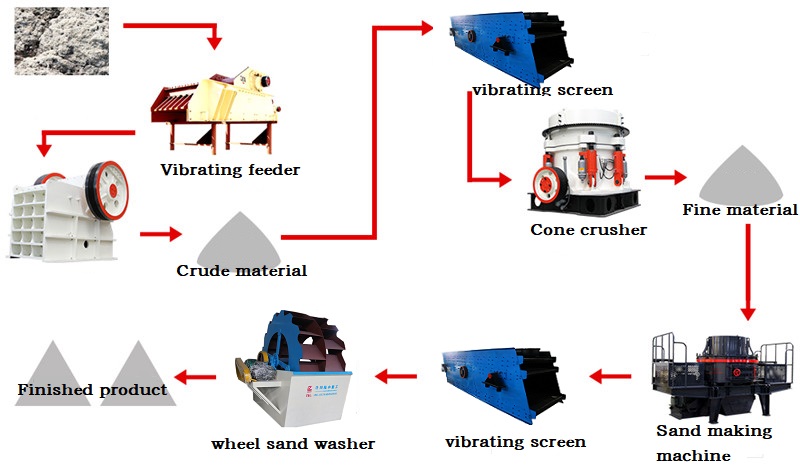

Equipment configuration: vibrating feeder, jaw crusher, multi-cylinder hydraulic cone crusher, sand making machine, vibrating screen, belt conveyor and other related equipment.

Selection of raw materials

The local granite is rich in resources, so granite is used as the raw material processing mechanism sand. The requirements for selecting a mine are shallow coverage of raw material mines, compliance with various physical and chemical indicators, stable quality, large reserves of minerals, and convenient transportation.

Target Products The mining company’s products are mainly positioned as building stones and construction sand. The specifications of building stones mainly include continuous grading and single grading products of 0 to 5 mm, 5 to 10 mm, 10 to 31.5 mm, and 31.5 to 60 mm. The specifications of construction sand mainly include Class I and Class II sands of 0 to 4.5 mm. According to market demand, rough stones with a particle size of less than 800 mm and stone powders with a particle size of less than 0.075 mm can also be provided. According to the characteristics of granite, the design of the above-mentioned system is designed according to the process flow to be four-stage crushing, that is, primary crushing, medium crushing, fine crushing and sand making. The first crush is open circuit production, and the mud removal facility is reserved; the medium crushing, fine crushing and sand making and the matching screening workshop form a closed loop production process to meet the needs of concrete aggregates of various grade ratios. The entire production line has a flexible process and the overall design is reasonable, reliable and adjustable.

1. Mining and road development. In combination with the actual situation of the mine, the mine development method adopts the development plan of on-site road development and automobile transportation. The total length of the highway trunk line is about 1800m, and the ore is transported to the unloading platform of the crushing workshop.

2. The first level of crushing and breaking the yard. The raw materials less than 800mm are transported by car to the unloading pit, and are transported by the vibrating feeder with the screening device; the material less than 150mm does not need to be broken, and falls directly onto the belt to enter the primary storage yard; the material larger than 150mm is crushed by the jaw. The machine is broken (discharge port 150mm), and the broken material enters the primary yard.

3. Breaking the system and screening. The medium-breaking system is relatively flexible in arrangement, and can be separated from the first-breaking system by the intermediate material library, and can be operated independently of each other. It can also be directly connected with the first-breaking system through the belt. Both arrangements have advantages and disadvantages. The mining company’s broken system consists of a thick cavity cone and a thin cavity cone connected in series, which should be called two broken and three broken. The material can be filtered through a heavy-duty sieve before the second break, which can increase the output and reduce the power consumption.

The medium breaking system and the vibrating screen system have a dust removing device. The material of the primary yard of the project falls to the conveyor belt of the underground gallery through the vibrating feeder, and is sent to a double-layer heavy-duty vibrating screen for pre-screening through the belt conveyor. The material less than 31.5mm is directly screened out into the cone discharge belt, which is larger than 31.5mm of material enters a coarse-cavity cone crusher. After the crushing and sieving, the material above 31.5mm enters a fine-cavity cone crusher to be further crushed. The mixture after being crushed by two cone crushers enters two sets. The layer circular vibrating screen is sifted, and the material sieves less than 31.5mm are divided into three specifications: 0-5mm, 5-13mm and 13-31.5mm.

4. Gravel storage. The three materials after the cone crushing and screening were transported through the belt into three 2500t round warehouses.

5. Gravel is distributed. The gravel is discharged from the bottom of the gravel storage tank through the arc valve into the belt and transported to two 300t gravel distribution warehouses, and loaded by the unloading device with the dust removal device.

6. Sand screening and stone powder sorting. The dry process is used, and the sand making equipment is arranged in 4 sets. The sand making raw materials are mainly composed of 0-13 mm material produced by the front cone crushing. Considering the sand making effect, a part of the material of 13-31.5 mm is appropriately added, and the sorting device is mainly used in combination. Type separator. The content of stone powder in sand is controlled at about 5%. Due to the dry process, in order to reduce dust in the distribution and transportation, the sand needs to be sprayed during the loading process. The sand making system, the vibrating screen system and the sorting system have a dust removing device. The sand-making raw materials are mainly mixed materials of 0-5mm, 5-13mm and parts of 13-31.5 mm. The three kinds of materials are transported into the sand making machine after being crushed by the bottom of the tank, and transported into the three-layer vibrating screen through the belt, and the materials returned by more than 5 mm are returned. The sand making machine continues to be broken (can also be sold as a finished stone), and the rest of the material is divided into 3-5 mm and less than 3 mm. The material less than 3mm is transported into the classifier by the belt conveyor, the stone powder and the sand are sorted, and the sorted sand and the 3-5mm material pre-screened in front are mixed into the finished sand.

7. Sand storage and distribution. The finished sand is transported by belt into two finished product warehouses, and the stone powder is transported into a 2500t powder store through the hoist. The finished sand is discharged from the bottom of the sand storage tank through the arc valve into the belt and transported to two 300t sand distribution warehouses. After the water treatment, the finished product is delivered to the factory. The stone powder is delivered to the factory through cement bulk equipment.

8. Electrical control. The total installed capacity of the whole plant is 6500kW, all of which are 0.4kV equipment. The equipment is all three types of power load (except the computer system and fire protection are equipped with UPS for important equipment to ensure equipment safety), and the rest do not set security power.

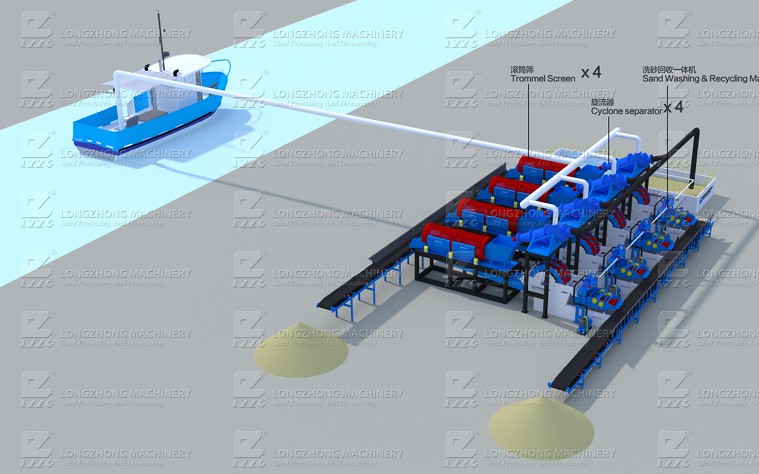

Equipment for extracting sand and gravel from river silt

Modular Construction Waste Processing Plant

Jigging machines for tungsten tin and gold ore dressing

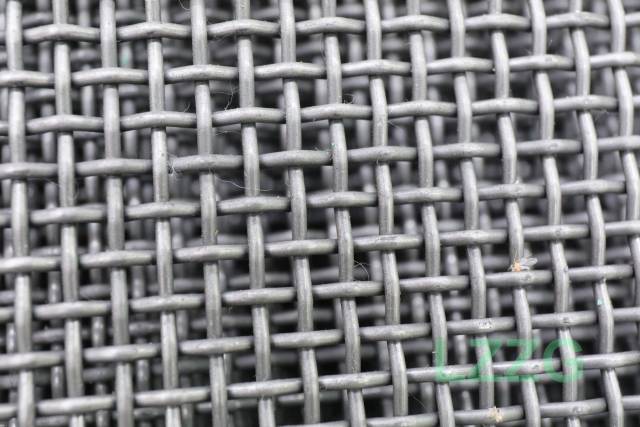

Mining wear-resistant manganese steel screen woven ore classification screen