Basalt (sand) is the best material among the stones used for repairing roads, railways and airport runways. It has strong compressive resistance, low crushing value, strong corrosion resistance, and asphalt adhesion. It has the advantages of less draft, poor electrical conductivity, strong compressive resistance, low crushing value, strong corrosion resistance, and asphalt adhesion, and has been internationally recognized as the best cornerstone for railway and road transportation.

Applicable materials for diabase sand production line: granite, basalt, diabase, cobblestone, limestone, cement clinker, quartzite, emery, ore, iron ore, etc.

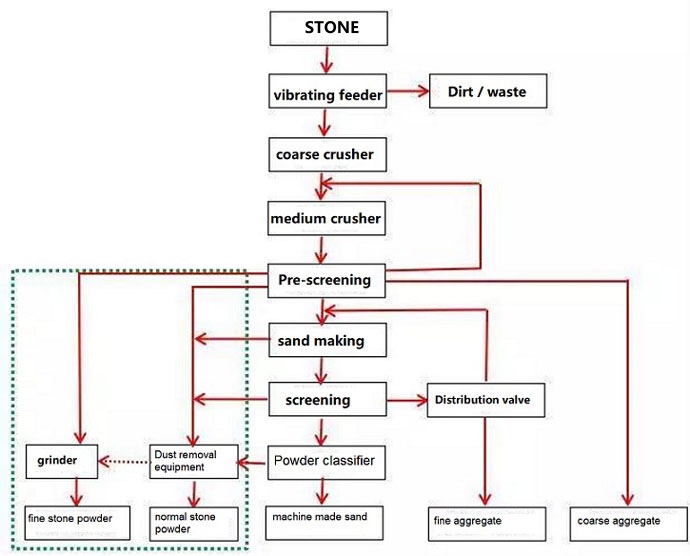

Process flow

The basalt sand making process basically includes feeding, crushing, sand making, screening, cleaning, and is configured according to the actual needs of users.

1. First, the material should be sent to the jaw crusher for preliminary crushing through the vibrating feeder;

2. The coarsely crushed basalt is moved by the belt conveyor to the cone crusher for further crushing;

3. Then it is sent to the vibrating screen for screening, and basalt materials of different specifications and returned materials are screened out;

4. The materials with qualified particle size will continue to be sent into the sand making machine for sand making operations, and the other part of the materials will be returned to be finely broken;

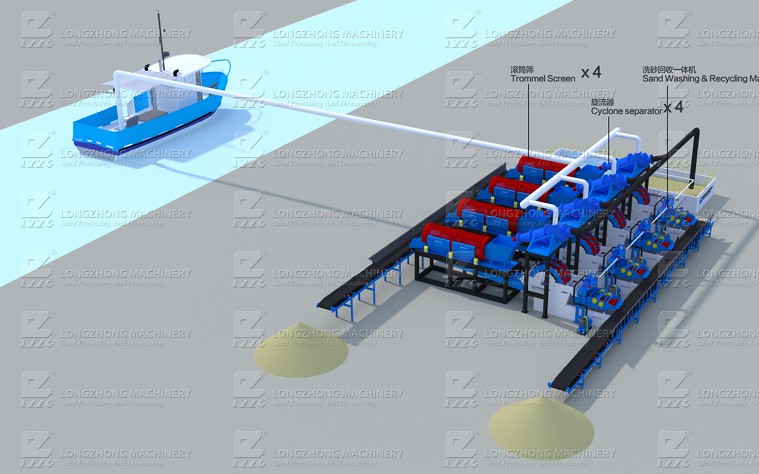

5. After the sand making is completed, according to the requirements of the finished material, the sand can be washed to obtain clean basalt sand.

Basalt sand production line application equipment

Feeder: The feeder is mainly responsible for the feeding operation in the sand and gravel production line. The equipment has a simple structure and is easy to operate.

Jaw Crusher: The jaw crusher is mainly used in the primary rough crushing “role” in the sand and gravel production line. This equipment has a large processing capacity and stable operation.

Cone Crusher: Cone crusher is used for medium and fine crushing of materials in sand and gravel production lines. It is very suitable for the crushing of basalt, pebbles, granite, iron ore and other high-hardness materials, and the wearing parts have a long service life. It has the advantages of large processing capacity, high crushing rate, simple maintenance and high degree of automation.

Impact crusher: Impact crusher, also known as sand making machine, is a commonly used equipment in stone shaping and sand making. It integrates three working modes of crushing, shaping and sand making. It is an ideal choice for processing construction sand.

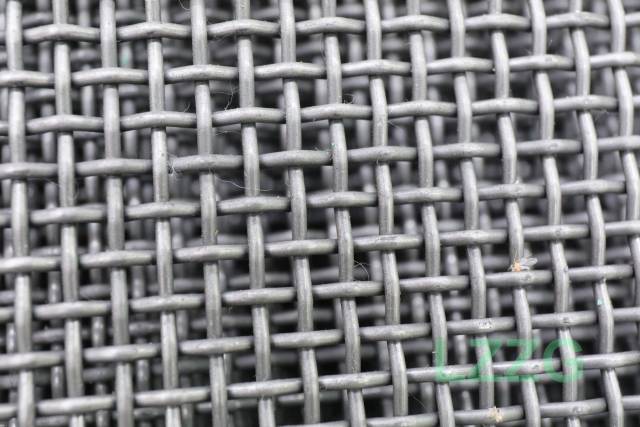

Vibrating screen: This equipment is mainly a kind of filtering and screening equipment in the sand and gravel production line. Sand and gravel screening is a must, after screening can be classified into stones and sand.

Conveyor: The conveyor is mainly responsible for material transportation in the sand and gravel production line. It is flexible in use, easy to control, can flexibly change the direction of transportation, and has strong operational stability. The conveyors configured in different production lines are different, mainly depending on the number of factories and equipment, and the length of the return journey.

Equipment for extracting sand and gravel from river silt

Modular Construction Waste Processing Plant

Jigging machines for tungsten tin and gold ore dressing

Mining wear-resistant manganese steel screen woven ore classification screen