Cyclone separator for fine materials classification

November.11,2019

November.11,2019

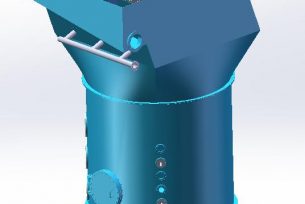

Fine sand cyclone separator instruction

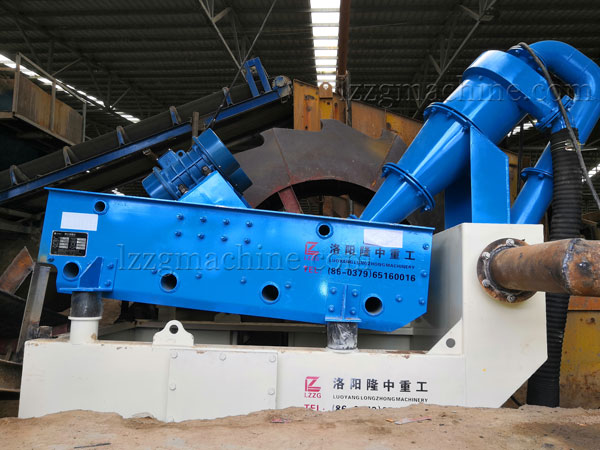

A Separator is a device installed in industrial applications to separate mixed objects. What is the main function of the cyclone in the fine sand recovery unit? The fine sand recovery unit is mainly used in the beneficiation industry for classification, sorting, concentration, and de-sludge. Hydrocyclone is used as a classification device, it can be used in a fine sand recovery device with a dewatering sieve, a slurry pump.

The working principle of the hydrocyclone of the fine sand recovery device is to use a sand pump (or drop) to screw the mud wastewater into the cylinder in a tangential direction at a certain pressure and flow rate, and then the slurry will rotate along the wall at a very fast speed. Centrifugal force is generated, and coarser and heavier ore particles are thrown out by centrifugal force and gravity to obtain the desired fine sand particle size.

In the fine sand recovery device, the thicker part of the cyclone is a hollow cylinder, and the thinner part below is an inverted vertebral body that communicates with the cylinder, and the two parts together form the working cylinder of the hydro-cyclone. In addition, the cyclone in the fine sand recovery device also has a delivery pipe, an overflow pipe, an overflow pipe and a grit outlet, etc., so that the cyclone recovery can be solved from the feeding and discharging. The problem of sand.

The hydro cyclone has no moving parts, not only has a simple structure; the production capacity per unit volume is smaller, the area is smaller, and the classification efficiency is higher. The effective classification rate can reach 80% to 90%, the classification granularity is fine, the cost is low, and the material consumption is low. . Therefore, he is an indispensable part for the fine sand recovery device.

In the fine sand recovery device, the cyclone acts as a sediment separator, which can separate the relatively heavy sediment in the sewage, and can also remove the water in the mud, so it is indispensable in the fine sand recovery device.