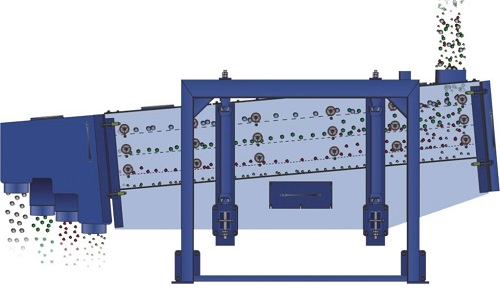

Silica sand vibrating screen, swing screen machine

July.05,2021

July.05,2021

Silica sand vibrating screen is an important equipment in the silica sand pickling production line and the micro silica fume production line. With the slow depletion of crystal resources, people began to use ordinary quartz to prepare high-purity quartz sand.

Quartz sand screening process

Quartz ore is washed and crushed into 8~10mm particle size, and then enters the roller grinding machine sand with a size of 0.4~0.1mm. Then enters the vibrating screen, and the sieved quartz sand is classified into 20 mesh, 50 mesh, 100 Mesh, 160 mesh, 200 mesh and other particle size specifications. Enter the mixing cleaning equipment for secondary cleaning to improve purity.

The quartz sand square swing screen is a tool for sieving powder and granular materials by simulating manual sieving. In order to meet the requirements of large output and high precision for screening materials, it is a screening machine that maintains the integrity of the shape of the material particles. Its structural feature is that its working method is to imitate the manual screening action of human beings for screening, and its swing frequency and amplitude can be adjusted. Overall, the effect is good.

Specific features

1. Up to 5 times the output per unit area;

2. It can achieve up to 6 levels of separation, and the screening efficiency is as high as 90%-99%;

3. The use of high-energy cleaning device systems such as silicone rubber balls and ultrasonics will prevent the sieve from being blocked. Airtight dust removal, safe operation;

4. The acceleration is 4-5 times lower than that of the vibrating screen, the life of the screening parts is increased and the maintenance is reduced;

High-purity quartz sand has excellent chemical stability, high insulation and pressure resistance and extremely low bulk expansion coefficient. It is an indispensable and important raw material for high-tech industries such as electronic core devices, optical communication materials, and solar cells. It is also a basic raw material for the production of quartz crucibles, monocrystalline silicon rod containers, and chips.

The main technical indicators of high purity quartz sand

1. The appearance is white with no visible mechanical impurities.

2. Purity requirements: The content of silica is greater than +99.99+.

3. According to the utilization of different industries, it can be processed into series of products of different specifications and models to meet user requirements.