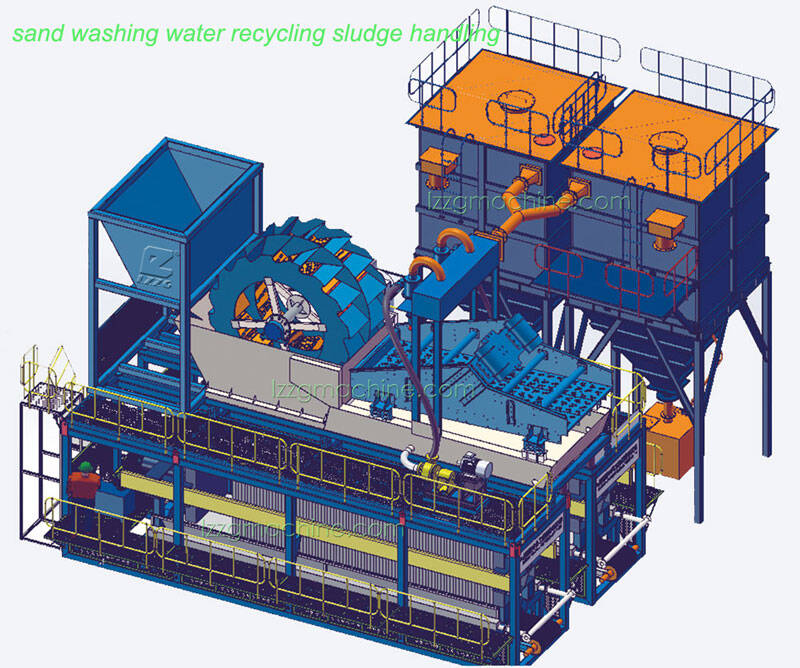

Modular sand washing and water recycling plant with sludge handling

September.29,2019

September.29,2019

Sand washing and water recycling plant save 90% water

In mining, aggregate processing, urban construction waste incineration, ceramic raw material processing, silica sand production and processing, various metal mine tailings treatment and many other industries, a wide range of screening and cleaning equipment is used to treat materials and tailwater purification, Solid waste (mud) dry heap treatment.

In order to solve the problems of large equipment occupation, poor processing effect, complicated material transportation, uneconomical and environmental protection, etc., the company has developed a modular sand washing recycling, tail-water purification, solid waste dry discharge equipment, in appearance and structure. There is a lot of innovation.

The modular sand washing recovery, tailwater purification, solid waste dry discharge equipment, increases the automation level of the device through the integrated design of the distribution wheel, the sludge thickening tank and the chamber filter press, so that the device can be Achieving independent feeding, increasing the treatment effect of the device on the sewage, so that the device can achieve zero discharge of the tail water of the production line.

Completed project

Improvements compared to the traditional sand washing equipment

The modular device effectively improves the traditional equipment when it is used, because the automation level is low, the material feeding is very inconvenient, and the continuous feeding can not be realized during the feeding.

During work, it is easy to appear that the material above the vibrating screen is too much, resulting in poor vibrating screen effect, or no material above the vibrating screen, resulting in low work efficiency.

The problem of poor sand and gravel treatment, poor quality of treatment, loss of sand and sand, and economical efficiency caused by the loss of some sand bodies, and the inability of the sewage to be properly disposed of, may cause environmental pollution.

Reasonable process design

Fine sand recycling structure

Firstly extracting the fine sand in the raw material slurry can effectively reduce the load of the subsequent equipment and reduce the type of the equipment, thereby achieving the purpose of small investment and small floor space, and can reduce damage to equipment components and prolong the service life of the equipment.

Sludge concentration structure

The process is reasonable, the fluid basically adopts the gravity self-flow mode to reduce the use of the pump, the power of the whole machine is small, energy-saving and environmental protection, and the treated water and mud can meet the relevant environmental protection requirements. Structural optimization, overall modular design, free combination, easy maintenance, and transportation.