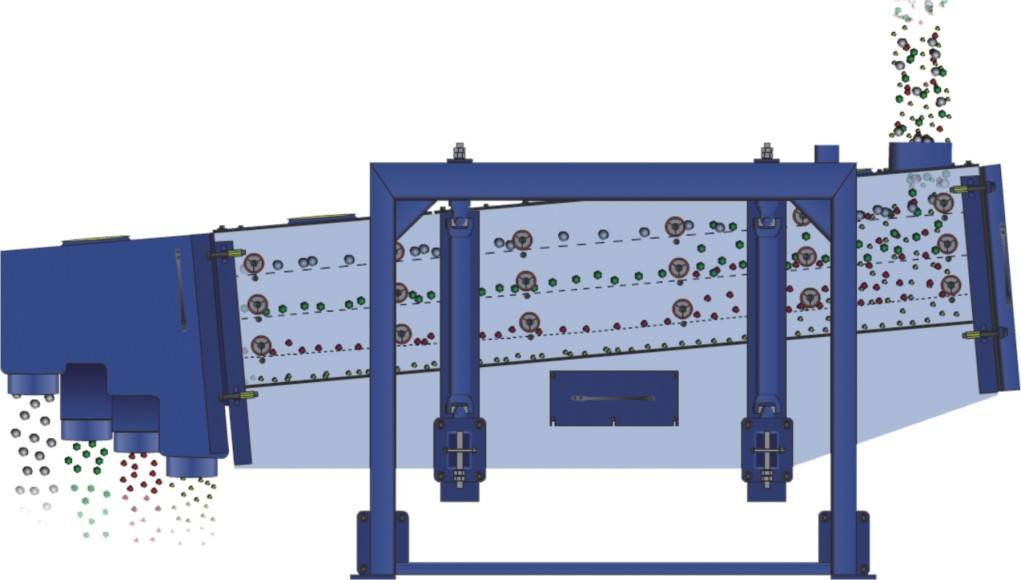

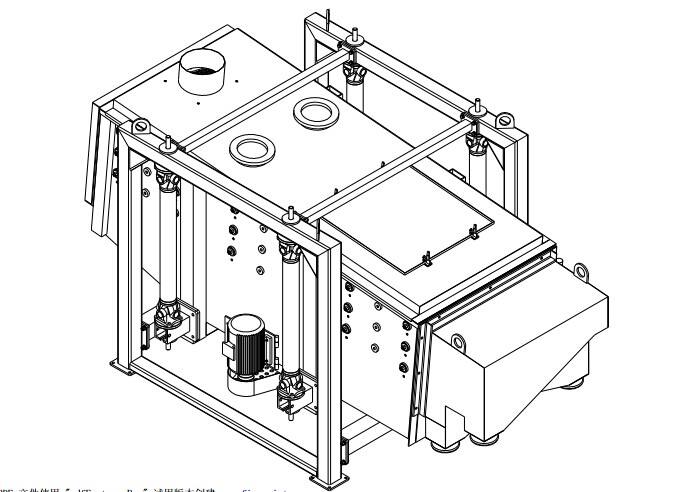

40~100 mesh quartz sand classification and screening machine

June.23,2022

June.23,2022

The square swing screen is also called a reciprocating screen. The vibration force generated by the driving device is an inertial force that changes in a certain direction around a fixed axis. Its essence is the reciprocating inertial force formed by the rotation of the eccentric wheel around the fixed axis. According to the structural characteristics and working principle of the swing screen, the screen surface is generally arranged horizontally or slightly inclined (the inclination angle is 0° or 5°).

The quartz classification machine also used in chemical and new materials, metallurgy, metal powder, mineral powder, food, salt, sugar, abrasive, feed, and other industries.

The working principle of the swing screen

After the screen machine is started, the shaker of the screen machine, that is, the screen box reciprocates back and forth under the action of the inertial force, and the screen box drives the screen surface to periodically shake, so that the materials on the screen surface move in a directional jumping motion with the screen box. During the period, the material smaller than the sieve surface diameter will fall to the lower layer through the sieve hole and become the under-sieve material, and the material larger than the sieve surface diameter will be discharged from the discharge port after continuous rolling and jumping motion, and finally the screening work will be completed.

The quartz sand swinging screen has higher processing capacity and screening efficiency than the general inertial vibrating screen. The trajectory of the movement is that the speed and acceleration are both nonlinear curves, so the material and the screen surface have more contact with the machine filter, of course, the screen penetration rate is increased.

The square rocking screen can further improve the screening efficiency by increasing the residence time of the material on the screen plate.

Pure pursuit of screening accuracy will cost the output; and the pursuit of large output will reduce the accuracy. The square rocking screen is redesigned for the above production problems of customers, so that it has a large processing capacity and at the same time ensures the screening accuracy. ;The processing capacity of a single unit is 5 times that of the traditional linear vibrating screen under the condition that the screening accuracy value remains unchanged; it effectively solves the problems of site limitation, excessive energy consumption, and increased labor costs.