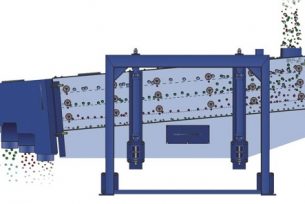

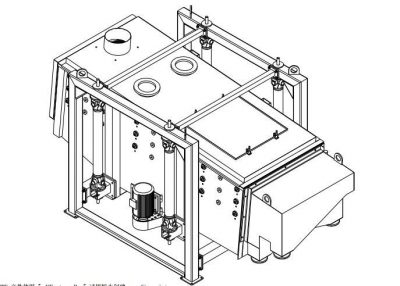

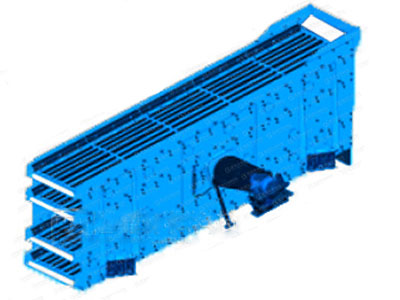

Square swing screen for frac sand screening

In order to solve the contradiction between screening accuracy and uneven output in the screening equipment industry, the square swing screen was developed and designed. It is highly efficient screening equipment with high precision and large output. It can be used in the chemical industry (soda ash, soda, fertilizer, Resin), food (additives, starch, salt industry, tea, etc.), metallurgy, metals, magnetic materials, activated carbon, quartz sand, and other industries.

Working principle

After the screen machine is started, the screen box reciprocates back and forth under the action of inertial force. The screen box drives the screen surface to periodically shake, so that the materials on the screen surface will make a directional jump movement with the screen box. The material smaller than the screen surface aperture After falling through the sieve hole, it becomes the sieve. The material larger than the hole diameter of the sieve surface is discharged from the discharge port after continuous tumbling and jumping movement to complete the screening work.

Product Features

Judging from the trajectory of the shaker of the screen machine, that is, the square swing screen, also known as the reciprocating screen, the vibration force generated by the driving device is an inertial force that changes around a certain axis and direction in a regular pattern, and its essence is caused by the eccentric wheel The reciprocating inertial force formed by rotation about a fixed axis. According to the structural characteristics and working principle of the square swing screen, the screen surface is generally horizontal or slightly inclined (the inclination angle is 0 ° -5 °).

Technical parameters

| model | Effective screening area (㎡) | Power (KW) | Screen angle (°) | Number of layers | Rotation frequency (r / min) | Screen box travel (mm) |

| XFYBS1030 | 3 | 3 | 5~8 | 1~5 | 180~260 | 25~60 |

| XFYBS1036 | 3.6 | |||||

| XFYBS1230 | 3.6 | 4 | 5~8 | 1~5 | 180~260 | 25~60 |

| XFYBS1236 | 4.32 | |||||

| XFYBS1530 | 4.5 | 5.5 | 5~8 | 1~5 | 180~260 | 25~60 |

| XFYBS1536 | 5.4 | |||||

| XFYBS1830 | 5.4 | 7.5 | 5~8 | 1~5 | 180~260 | 25~60 |

| XFYBS1836 | 6.48 | |||||

| XFYBS2030 | 6 | 7.5 | 5~8 | 1~5 | 180~260 | 25~60 |