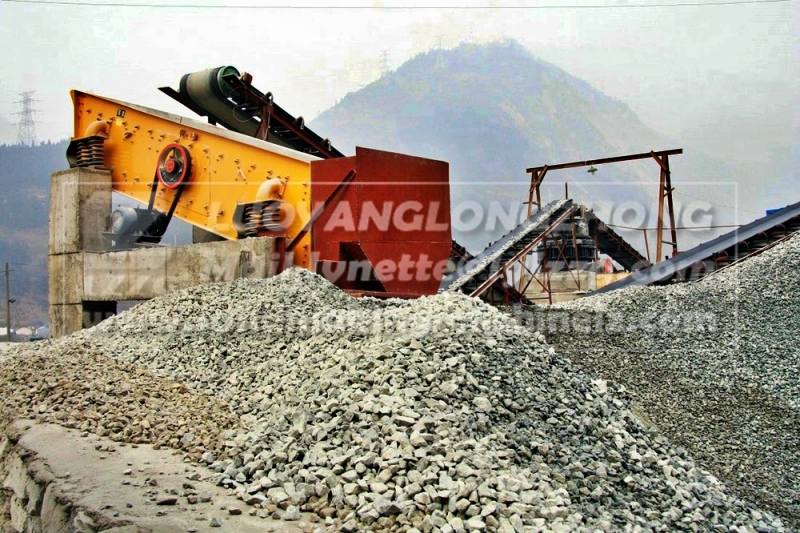

Limestone, granite, basalt crushed stone production line

December.19,2019

December.19,2019

Crushed stone production line is a special production line for sand and stone used in construction, highway, railway and other industries. The main equipment includes jaw crusher, impact crusher, impact crusher, vibrating feeder, vibrating screen, sand washing machine.

The crushing stone production line is mainly composed of vibration feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electric control and other equipment. The designed output is generally 50-500 tons/hour. To meet customers’ different processing needs, dust removal equipment can be equipped. It can be used for aggregate and artificial sand making of limestone, granite, basalt, river pebble and other materials. It is suitable for applications in hydropower, building materials, highways, urban construction and other industries. According to different process requirements, various types of equipment are combined to meet different process requirements of customers.

Workflow

1. Large pieces of stone are evenly fed into the jaw crusher by the vibrating feeder through the silo for coarse crushing. The coarsely crushed stone is sent to the impact crusher by the belt conveyor for further crushing. The finely crushed stone is sent to a vibrating screen by a belt conveyor for screening. Several stones of different specifications are screened out. The stones that meet the particle size requirements are sent to the finished product pile by the finished belt conveyor.

2. The stones that do not meet the particle size requirements are returned to the impact crusher by the belt conveyor for further crushing, forming a closed circuit multiple cycles. The granularity of the finished product can be combined and classified according to user needs. To protect the environment, auxiliary dust removal equipment can be equipped.

Main Features

The production line has a high degree of automation, and the entire production line requires almost no manual operation except for equipment startup and shutdown and daily maintenance. It has high production efficiency, low operating cost, large output, and high yield. The finished stone has a uniform particle size and good shape, which meets the national high-speed material requirements.