Stone powder treatment process in dry process sand making plant

November.10,2023

November.10,2023

What is dry sand making technology

Dry sand making is a machine-made sand production process. The raw materials are sent to the crusher through the feeder for crushing. The raw materials are crushed to less than 5 cm and sent to the sand making machine for sand making. After the sand making machine, the raw materials are crushed into sand grains of less than 5 mm and transported. machine to the finished product pile. The production process does not require water. It mainly removes powder through negative pressure in the dust box or positive pressure in the powder separator or a combination of the two. It uses wind to remove powder, so that the powder content of the machine-made sand is low, and the dust will also be removed. Collected as a by-product, dry sand making is suitable for areas with severe water shortages.

The equipment used in dry sand making is:

Hopper, vibrating feeder, belt conveyor, sand making machine, vibrating screen, elevator, powder separator, silo group and dust collector. These equipments together form a dry sand making production line, which can crush and process raw materials into sand that meets the requirements.

Dry machine-made sand has many advantages

1. To save water resources, sand plants can be built in areas lacking water resources.

2. The finished product has low moisture content.

3. The process is simple and the equipment occupies a small area.

More Advantages of dry sand making plant

Disadvantages of dry process sand making

1. Uneven thickness: The preparation process of dry machine-made sand is easy to form some fine pores and cracks, resulting in uneven thickness and unreasonable gradation, and the commercial mixing station cannot be used directly.

2. Poor particle shape: The particle shape of dry machine-made sand is irregular, with many bulges and sharp angles on the surface.

3. There is a certain amount of stone powder residue on the aggregate surface of the product, which is not clean and has a poor look and feel.

How to deal with high stone powder content

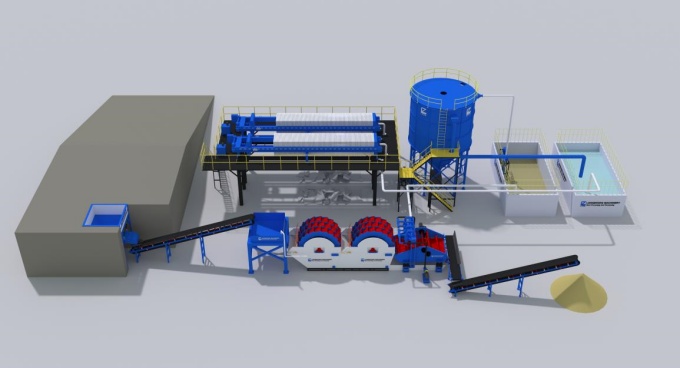

In response to the above shortcomings, Longzhong Heavy Industry customized a complete production line for it. The production line consists of complete sets of equipment such as silos, conveying equipment, sand washing and fine sand recovery equipment, trihydrogen purification bodies, and sludge filter presses.