Slica fracturing proppant production equipment

March.22,2021

March.22,2021

Manufacturing method and equipment of special quartz fracturing sand for oil field

The raw material quartz sand flows into the spiral sand washing machine through the sand tank for rough washing;

Send it to the cylindrical sand washing and screening machine for secondary washing, and reach the turbidity standard ≤100FTU;

Stirring by the dehydration spiral sand washing machine, destroy the moisture layer on the surface of the coated sand particles, and perform dry cleaning and dehydration;

Transported to the dehydration equipment to stand for dehydration to reduce the water content to below 20%, and the time is 20-30 minutes;

Transported to the rotary cylindrical quartz sand drying furnace at 90~120℃, heated for 25~30 minutes to be dried;

The dry quartz sand is screened with a trommel screening machine, and the particle size is 0.425-0.85 mm for special quartz fracturing sand; this method improves production efficiency, guarantees product quality, and is not affected by weather, environment and seasonal changes. Industrialized production.

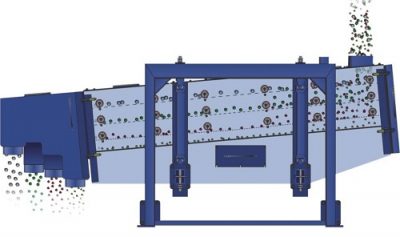

Fracturing sand vibration screening, machine Fracturing sand swing screen.

The simple screening of the swing screen (square screen) is sieving with both eyes and hands. The swing screen is a mechanical simulation of this. It is currently effective to simulate the effective principle of manual screening movement (screening accuracy, efficiency, screen mesh). The service life is 5-10 times that of conventional round screens), which meets the fine and ultra-fine range of powder and particulate materials, especially suitable for materials that are difficult to handle.

The principle of fracturing sand to obtain oil

Quartz oil fracturing sand has high fracturing strength and is mainly used for downhole support in oil fields to increase the output of oil and natural gas. It is an environmentally friendly product. This product uses natural quartz as a raw material, and is a substitute for medium and low-strength proppants such as ceramsite, glass balls, and metal balls. It has a good effect on increasing oil and gas production.

When oil and natural gas are exploited in deep wells, the high-closure pressure and low-permeability deposits undergo fracturing treatment to crack the oil and gas-bearing rock formations, and oil and gas are collected from the channels formed by the cracks. Quartz sand support material enters the formation along with the high-pressure solution to fill in the cracks of the rock formation, which plays a role of supporting the cracks not to be closed due to stress release, thereby maintaining high conductivity, allowing smooth oil and gas and increasing production. Practice has proved that oil wells fracturing with quartz sand proppant can increase production by 30-50% and extend the service life of oil and gas wells.

Specification of quartz fracturing sand

According to the specifications, they are: 12-20 mesh, 16-20 mesh, 16-30 mesh, 20-40 mesh, 30-50 mesh, 40-60 mesh, 40-70 mesh, 70-100 mesh, etc. In order to meet the needs of oil and gas wells at home and abroad, users can choose products of different strengths and specifications according to the depth of the oil well.