Difference between vibration exciter and the vibration motor working principle

July.12,2019

July.12,2019

The vibration motor and the vibration exciter are common mechanical equipment. The following is the main knowledge of the two so that you can understand the difference between the two. The vibration motor is an excitation source that combines the power source and the vibration source. The vibration motor is equipped with a set of adjustable eccentric blocks at both ends of the rotor shaft, and the centrifugal force generated by the high-speed rotation of the shaft and the eccentric block is used to obtain the excitation force.

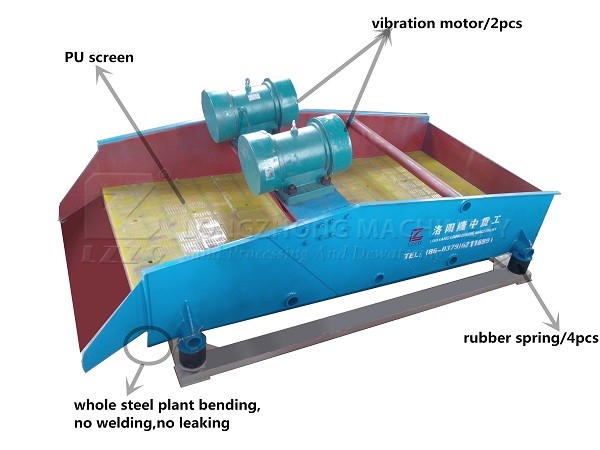

vibrating screen with vibration motor

The working principle of vibration motor

The vibration motor is an excitation source that combines the power source and the vibration source. The vibration motor is equipped with a set of adjustable eccentric blocks at both ends of the rotor shaft, and the centrifugal force generated by the high-speed rotation of the shaft and the eccentric block is used to obtain the excitation force. The vibration motor has high excitation force utilization, low energy consumption, low noise, and long life. The vibration force of the vibration motor can be adjusted steplessly. It is easy to use and can be applied to general vibration machinery, such as vibration crusher, vibrating screen machine, vibration baler, vibration drop machine, vibration molding machine, vibration pile driver, vibration lifting. machine.

The exciter is used to generate an excitation force and can apply such an excitation force to other structures and devices. The exciter can obtain a certain amount and magnitude of vibration of the exciting object, thereby vibrating and testing the object. , or calibrate vibration test instruments and sensors.

vibrating screen with vibration exciter

The working principle of the vibration exciter

The one-way inertial exciter generally consists of two rotating shafts and a pair of gears with a speed ratio of 1. The two rotating shafts rotate in opposite directions at opposite speeds, and the two eccentric blocks on the shaft generate a resultant force of inertial forces in the Y direction. When working, the exciter is fixed on the driven member, and the excited member obtains the required vibration.

The electric exciter passes the alternating current into the moving coil, causing the coil to vibrate by the electromagnetic excitation force in a given magnetic field. The constant magnetic field of the electric exciter is generated by the direct current flowing into the exciting coil, and then the alternating current is passed into the moving coil, and the moving coil is subjected to the cyclically varying electromagnetic exciting force to drive the jack to reciprocate. The desired vibration can be obtained by bringing the ram into contact with the driven member.

The electromagnetic exciter inputs a periodically varying current into the electromagnet coil and a cyclically varying excitation force is generated between the excited member and the electromagnet. Electromagnetic exciters used in vibrating machinery usually consist of an electromagnet core with a coil and an armature, with a spring between the core and the armature. When alternating current is input to the coil, or alternating current plus direct current, or a half-wave rectified pulsating current, a periodically varying excitation force is generated. This exciter usually fixes the armature directly to the working part requiring vibration.

Vibration motors and vibration exciters are two types of vibration sources widely used in practical engineering. They have almost the same wide application range. In many cases, these two types of vibration sources are sometimes interchangeable, but we believe that various types of vibration The scope of the vibrator is wider than that of a general vibrating motor.