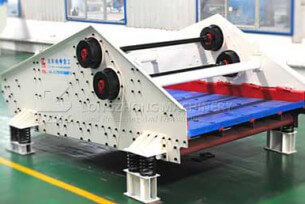

Flip-flow screen for sand, coal, silica separation

July.19,2018

July.19,2018

The flip-flow screen is suitable for damp and difficult screening materials and is combined with the circular sieve screening technology and the toothed screen technology. The relaxation process of the sieve screen can avoid the blockage of critical particles and the problem of material blocking and blocking. It can effectively solve the complex and diverse screening requirements of construction waste aggregates and is suitable for the moisture content of domestic garbage, construction, coal mine, etc. %-14% wet material screening and large material screening.

The flip-flow screen is a combination of the circular sieve screening technology and the toothed screen technology. It is suitable for wet and difficult screening materials, effectively solves the complex and diverse screening requirements of construction waste aggregates, and is suitable for domestic garbage, coal mine, and other moisture content. In the case of 7%-14% wet material screening, the needle-toothed imported polyurethane screen is suitable for screening large materials such as construction waste. The screen relaxation process can avoid the blockage of critical particles and the problem of material adhesion and block. The relaxation screen features large elasticity, stable vibration, high life, closed type, and compact structure.

Product advantages:

1. flip-flow sieve relaxation process can liberate the blockage of critical particles, avoid material adhesion and blockage problems; needle-toothed screen, suitable for screening large materials such as construction waste.

2. Effectively solve the problem that the moisture content is 7%-14%, and these wet materials are difficult to screen and easily block the net.

3. The flip-flow screen is an imported polyurethane sieve with high elasticity and high service life;

4. Closed screen body, environmentally friendly and compact.

5.Suitable for a variety of materials. Fertilizer, plastics, sand, gravel, calcium, carbonate, silica, feldspar, silicon, iron ore, non-ferrous metal ore.

Product parameters:

| Model | Maximum feed size (mm) | Screen Layers | Drive Power (KW) | Screen box tilt angle | Whole weight (t) | Dimensions (mm) |

| CZ1550 | 250 | 1-2 | 15 | 18 | 14 | 6100*2945*2400 |