Tailings treatment technology and tailings recovery equipment

April.15,2021

April.15,2021

The mud and slag discharged by mining enterprises after the completion of mineral processing have accumulated to form tailing ponds.

How to deal with tailings?

Utilization Value Of Tailings

At present, the treatment method of tailings is generally used as filling material for underground mining goaf, that is, water sand filling or cemented filling aggregate, or some directly cover soil on the tailings accumulation site to make fields, plant crops or afforestation.

In fact, the most cost-effective treatment of tailings is to make sand from tailings and as raw materials for building materials.

For example, the treated tailings can be used as raw materials for cement, tiles, aerated concrete, permeable bricks, refractories, fireproof and thermal insulation materials, glass, ceramsite, concrete aggregates, etc. tailings sand can be used instead of part of the machine-made sand to make concrete, build roads, pavement materials and so on.

Tailings Recovery Technology

Tailings water treatment technology: The tailings pond is a large-volume sedimentation storage pond, which can be set up on valleys, slopes, river beaches or flat ground by using topography, and surrounded by dams. Drainage wells and drainage pipes are set in the pond, or drainage ditches are set along the edges, and the tailings water is clarified and purified in the pond and overflows and discharges.

The suspended solids in the tailings water are deposited and stored at the bottom of the pond. Waste water stays in the pool for at least one day and night. This method can effectively remove suspended solids in wastewater, and the content of heavy metals and flotation reagents is also reduced. The longer the residence time, the better the treatment effect. The overflow water of the tailings pond can be recycled.

Gravity separation, magnetic separation and simple flotation of single metal ore do not require high water quality, and the water recycling rate can reach 80%, or no drainage at all. When the tailings particles are extremely fine and part of them are in a colloidal state, a coagulant can be added to the tailings water to accelerate the clarification process and improve the treatment effect.

Tailings Recovery Equipment

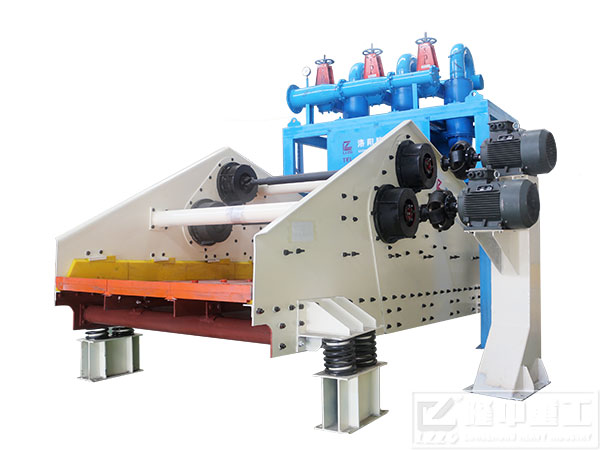

Tailings sludge dewatering machine

Dry tailings discharge screen