Dewatering methods for making bricks from sludge

December.02,2021

December.02,2021

Natural drying

Natural drying can be divided into two types: sand drying field and drying field. The former is used for the dewatering of the sediment in the grit tank; the latter is used for the dewatering of primary sedimentation sludge, humic sludge, digested sludge, chemical sludge and mixed sludge. The moisture content of the dried mud cake is generally 75% to 80%.

The sludge drying plant is an older and simpler method of sludge dewatering. It mainly relies on three methods of permeation, evaporation and skimming to remove water. However, as the nature of the sludge is different from the local weather conditions, the proportion of water removed by permeation, evaporation and skimming is also different. This method takes a long time to dehydrate, requires a lot of maintenance and management work, and produces stench and flies due to the corruption of the sludge, which affects the surrounding environmental sanitation. Therefore, it is only suitable for sludge treatment in small sewage plants.

Sludge thickening

Sludge thickening is the most economical and effective way to reduce the volume of sludge. No matter what method is used for sludge treatment, sludge thickening is essential. At present, the most commonly used methods of sludge thickening are: gravity concentration, air flotation concentration, centrifugal concentration and hydrocyclone concentration.

Gravity concentration

Gravity concentration is the purpose of thickening sludge by forming a high-concentration sludge layer during precipitation. Separate gravity concentration is completed in a separate gravity concentration tank. The process is simple and effective, but it may produce odor when the residence time is long; the gravity concentration method is suitable for primary sludge, chemical sludge and biofilm sludge.

Air flotation concentration

Air flotation concentration is the opposite of gravity concentration. It relies on a large number of tiny bubbles attached to the surrounding sludge particles to reduce the specific gravity of the particles and force them to float. Therefore, the air flotation method is particularly suitable for sludge with a contrast weight close to 1. The air flotation concentration method is easy to operate, has a certain odor during operation, has a high power cost, and is sensitive to sludge settling performance (SVI); it is suitable for activated sludge treatment systems with small remaining sludge production.

Centrifugal concentration

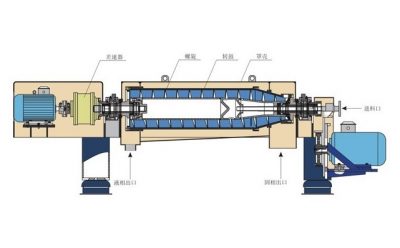

Centrifugal concentration is to use the different centrifugal force of the solid and liquid specific gravity in the sludge to concentrate. The characteristics of centrifugal concentration are self-contained system, good effect and easy operation; but higher investment, higher power cost, and higher maintenance level; suitable for large and medium-sized sewage plants biological and chemical sludge.

Hydrocyclone concentration

Hydrocyclone concentration is to use the centrifugal sedimentation and separation phenomenon produced by the cyclone to replace the centrifugal sedimentation and separation in the mechanical rotating body to achieve the purpose of concentration. However, the operation of hydrocyclone thickening is complicated, and it is easy to be clogged by thickening. Large-scale sludge thickening devices are rarely used.