Treatment and utilization of slag in garbage power plant

November.17,2022

November.17,2022

The main components of slag produced by domestic waste incineration power generation include slag, glass, ceramics, stones, etc., and most of them are similar in appearance to porous, light gray sand. Although slag is a solid waste, according to the instructions in GB18485 “Domestic Waste Incineration Pollution Control Standards”, slag is a renewable resource that supports and strongly encourages the development.

The new process of slag treatment of Longzhong Heavy Industry creates new value for resource utilization

Slag treatment is mainly to use the difference between the physical properties of each component of ash slag for screening, crushing, impurity removal, magnetic separation, non-ferrous metal sorting, precious metal sorting, tailing sand recovery, sewage wastewater treatment process and other resource links, to achieve the recovery of iron, copper, zinc and other valuable metals, after sorting slag to prepare recycled blocks, finished sand can be used for road base and bottom base aggregates.

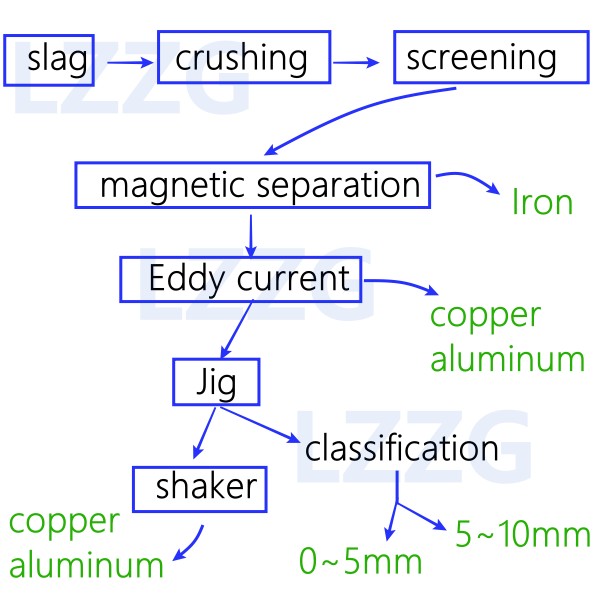

Production process:

Extracting gold, silver, copper, iron, aluminum and other metals from domestic waste slag

Feeding: Loading by forklift

Screening: the drum screen equipment is used to divide the slag into coarse slag and medium slag, which is convenient for the next step of circulating magnetic separation and crushing; The drum screen is used to divide the jigging material into coarse material and fine material, which is convenient for the coarse material to be sorted and crushed by circulating eddy current in the next step to improve the sorting rate of copper and aluminum.

Crushing: The slag crusher is used to reduce the slag particle size step by step to reduce and crush in order to improve the metal sorting rate; A blacksmith is used to break up and disperse the iron slag mixture.

Magnetic separation: the iron slag mixture in the slag is separated for crushing; The iron blocks and iron powder in the slag are separated for recycling.

Eddy current sorting: The eddy current sorting machine is used to sort and recover the aluminum metal in the slag.

Gravity sorting: using a jig and shaker to sort and recover copper metal.

Crushing: Crushing again to further grind the material, and the powder is discharged through the discharge grate to complete the grinding operation.

Sand washing: the material is cleaned under the rotation of the impeller to remove the impurities covering the surface of the sand and gravel, and the cleaning machine is completely dehydrated, which can effectively reduce the powder content of the material.

Dewatering: the separated metal is dehydrated by vibrating dewatering screen; The dewatering screen separates water and sand, and the moisture content of the finished material after dehydration is low.

Filter press: the sediment after precipitation is filtered by a filter press, and the clean water flows into the clean water pool for production and recycling, and the mud biscuits are discharged.

After the treatment of the product to achieve resource utilization, environmental protection sand is directly used for road laying materials, can also be made into environmentally friendly bricks, and cement concrete, directly turning waste into treasure; The sorted metal substances can be processed into metal products in metal processing plants. The entire slag resource process ensures that the slag is comprehensively treated, so that the garbage is opened one kilometer after the **** and truly recycled.