Sand Making Factory Design and Build: From Rock to Pure Sand

April.25,2022

April.25,2022

LZZG is a manufacturer of sand making and washing equipment. It designs and builds sand making plants for customers, including a full set of sand-making and washing equipment and sewage purification equipment.

Sand and gravel aggregate fine crushing and screening production line

In order to solve the problems of silica sand classification, material washing, tailwater purification, solid waste dry discharge, and other production line problems, the silica sand cleaning, fine crushing and screening production line is developed and designed. This production line can not only achieve material classification and washing but also save resources. Reduce water consumption and comply with environmental protection.

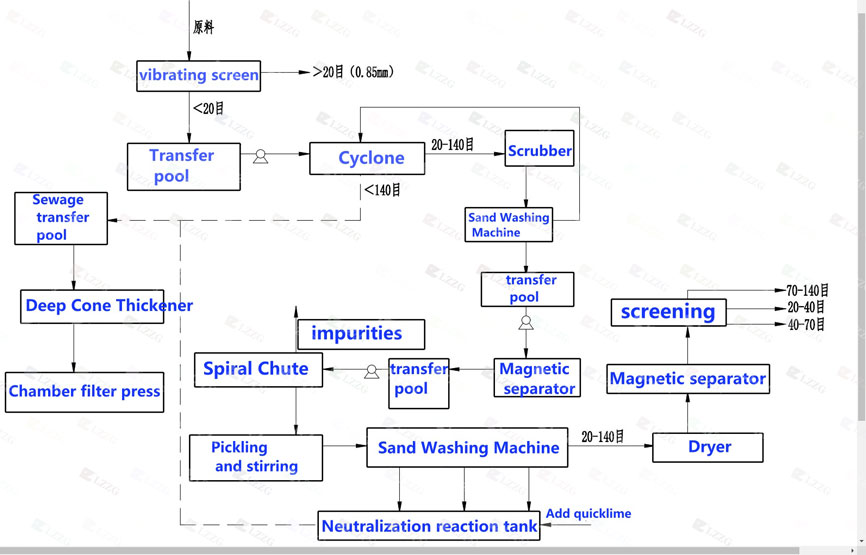

Production line process

Large pieces of silicon ore are initially crushed by jaw crusher, and the produced coarse material is transported by conveyor to cone crusher for secondary crushing.

The finely crushed silica is sieved into the vibrating screen to separate out two kinds of stones. The materials that meet the feed size are processed into sand-making sand particles for shaping, and the materials that do not meet the feed size of the sand making machine are subjected to secondary crushing to meet the particle size requirements.

Then, the silica sand that meets the specifications is magnetically separated by the magnetic separator and enters the cleaning water tank of the sand washing and recycling integrated machine. After that, the coarse-grained materials are sent to the dewatering screen by the salvaging wheel for dehydration.

The tail water is pumped into the separator by the slurry pump, and the sediment is separated by the separator. After recovery, the fine material is discharged to the screen surface of the dewatering screen and the coarse material is evenly mixed and dehydrated before discharging. At the same time, the sludge-water suspended matter treated by the separator is discharged into the sewage tank, and then the tail water is pumped from the sewage tank into the concentration tank by the pump for the mud-water separation operation. The concentrated mud is pumped into the plate and frame filter press through the bottom of the filter tank to achieve dry stacking. After pressure filtration, the clean water enters the clean water tank to realize the recycling of clean water.