Causes of Slurry Pump Wear and Repair Methods

July.12,2021

July.12,2021

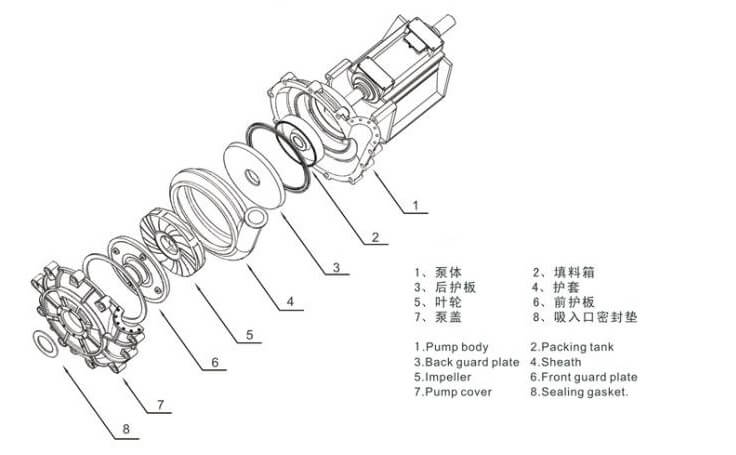

Slurry pump is a kind of impurity pump used to transport solid-liquid mixture. It can be used in mining, electric power, metallurgy, coal, environmental protection and other industries to transport slurry containing abrasive solid particles. Due to the transportation medium, the slurry pump often suffers from erosion and abrasion, so how to repair and protect against erosion has become an urgent problem for many companies.

Causes of scouring and abrasion of slurry pump:

1. During the operation of the slurry pump, the solid particles carried in the liquid impact the surface of the flow-through parts at a certain speed, causing material loss. According to the analysis of the worn surface of the failed component, the erosion wear mechanism can be divided into cutting wear, deformation fatigue wear and cutting + deformation coincident wear.

2. During the operation of the pump, in a local area of the flow-through component, for some reason, when the pressure of the pumped liquid drops to the vaporization pressure at the current temperature, the liquid begins to vaporize there, generating steam and forming bubbles. These bubbles flow forward with the liquid, and the metal surface is fatigued and peeled off by the impact, causing material loss. In severe cases, the metal surface appears honeycomb.

3. When the conveyed medium has a certain pH, the flow parts of the slurry pump will also undergo corrosion and wear, that is, the loss of materials under the combined action of corrosion and wear.

After understanding the reasons for the erosion and wear of the slurry pump, we can select the appropriate process according to the on-site construction environment and practical operating cost of the equipment. Due to the high cost of the slurry pump itself, many companies consider cost savings. In this case, considering the quality of the material itself, conventional surfacing, etc. are screened out. Repairing with polymer materials can solve this problem well, and the material has excellent mechanical and physical properties, high wear resistance, high heat resistance, high strength, and corrosion resistance, and fully meets the conditions for anti-scouring protection and treatment.

Operation steps for repairing erosion and wear of slurry pump:

1. Surface treatment: sandblasting treatment on the part to be repaired;

2. Cleaning: Use absolute ethanol to clean the over-current parts and the positions to be protected after sandblasting;

3. Strictly reconcile Soleil carbon nano polymer materials in proportion;

4. Smear and repair the grooves and pits that are washed and worn;