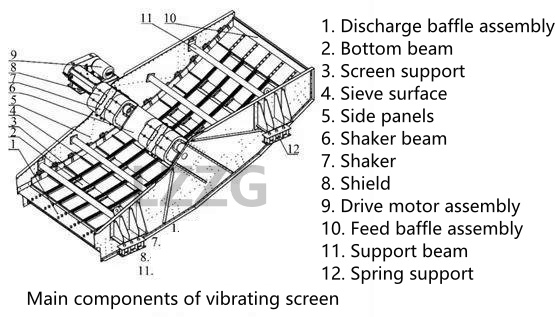

Vibrating screen structure diagram

February.11,2022

February.11,2022

circular vibrating screen structure and working principle

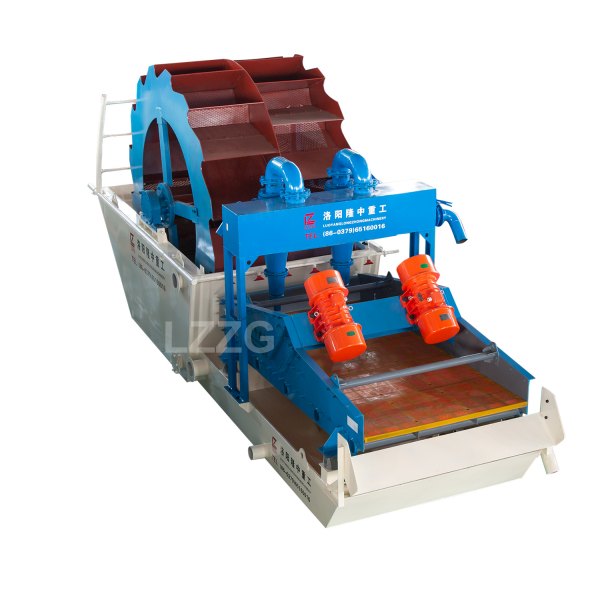

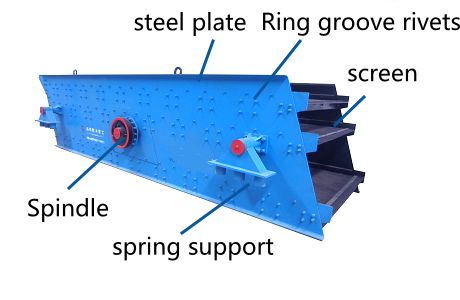

The circular vibrating screen is mainly composed of a screen box, a screen, a vibrator and a damping spring. If there are no special requirements, the YA and 2YA types are braided screen surfaces, and the YAH type is a punching screen surface. All types of screen surfaces can be applied. YA series circular vibrating screen is mainly composed of eccentric block exciter, screen box, motor, and supporting device. Adopting the structure of small amplitude, high frequency and large inclination angle, the machine has high screening efficiency, large processing capacity, long life, low power consumption and low noise. YAX thin oil circular vibrating screen structure: It is composed of spring support group, transmission device, screen box, support seat, thin oil lubricating vibrator, etc.

The circular vibrating screen is mainly composed of a screen box, a screen, a vibrator and a damping spring. The vibrator is installed on the side plate of the screen box, and is driven by the motor to rotate through the V-belt to generate centrifugal inertial force, which forces the screen box to vibrate. This series of screen machines are seat-mounted. The adjustment of the inclination angle of the screen surface can be realized by changing the height of the spring support.

It is mainly used in coal preparation, mineral processing, building materials, electric power and chemical industries.

Banana Sieve

Banana sieve is a kind of vibrating screen specially used for sieving rubber powder and coal, which has the advantage of high output.

The banana vibrating screen has a slope at the feeding end, which starts at 34°, and then descends at a number of angles to the discharge end, which is about 10°. The screen surface adopts the form of broken lines with different inclination angles, and the thickness of the material layer is unchanged from the feeding end to the discharging end. The ratio of material volume to flow rate on the screen surface of each section is stable, the material layer is high, showing a uniform state, and the screening efficiency is significantly improved, which is 1-2 times higher than that of the vibrating screen of the same area. When the content of the material whose particle size accounts for less than 1/2 of the graded particle size is large, the banana vibrating screen has high screening efficiency.