Tailings slag concentration dry discharge process

July.26,2023

July.26,2023

Dry slag discharge is a new tailings disposal process that has emerged in recent years. It refers to the multi-stage concentration of the tailings slurry output through the beneficiation process, and then processed by high-efficiency dehydration equipment such as dehydration vibrating screens to form a low-water content, easy to precipitate and solidify. And the slag that is conducive to site storage, the slag can be transferred to a fixed location for dry storage.

Application field: It is mainly used in the concentration and dehydration process of tailings in mineral processing plants to achieve the purpose of dry stacking of tailings, thereby avoiding environmental pollution. It is the preferred process for implementing green mines.

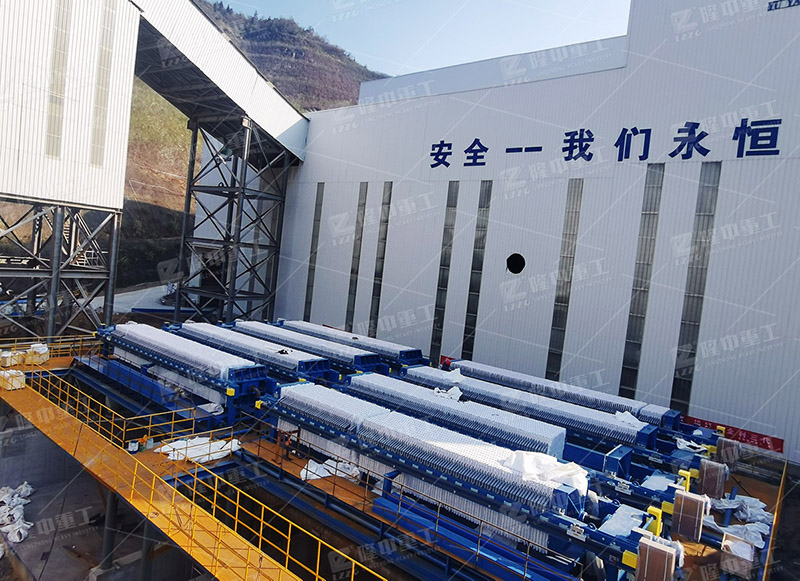

1 Combination of cyclone and dewatering vibrating screen: After the tailings are concentrated by the cyclone, the underflow enters the high-frequency vibrating dewatering screen for dehydration, so that the water content of the tailings can be kept within 16%, and the overflow of the cyclone and the dewatering screen The lower fine particle materials are usually dehydrated by thickeners and filter presses, so as to achieve the purpose of tailings dry-draining and stacking.

2. Directly use concentrators and filters to filter: This method has a relatively large initial investment and a small scope of application. Sometimes it cannot meet the production efficiency or dehydration degree.

Using the cyclone + dewatering screen process has the following advantages:

1. The technology is mature and the tailings dehydration effect is good. It can make the final tailings concentration reach more than 85%, and meet the requirements of dry discharge.

2. The production line operation cost is low. The unique equipment combination of the tailings dry discharge process makes the equipment investment and civil construction investment very small, and the Jinpeng patented equipment has good dehydration effect, low energy consumption, greatly extended service life, and further reduces operating costs.