slime water treatment process of coal washing plant

October.07,2021

October.07,2021

Sewage treatment in coal washing plants generally includes the following three levels of treatment:

The primary treatment is to remove stones, sand and fat, iron ions, manganese ions, grease, etc. contained in sewage through mechanical treatment, such as grilles, precipitation or air flotation.

The secondary treatment is biological treatment, the pollutants in the sewage are degraded and converted into sludge under the action of microorganisms.

The tertiary treatment is the advanced treatment of sewage, which includes the removal of nutrients and the disinfection of the sewage through chlorination, ultraviolet radiation or ozone technology.

Depending on the treatment goals and water quality, some sewage treatment processes do not include all the above processes.

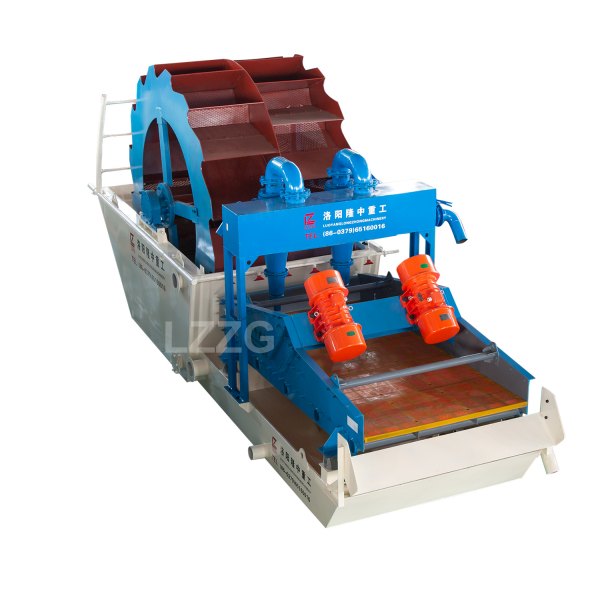

Coal slime waste water treatment process

The integrated treatment equipment and coal washing water will first flow into the regulating tank. The sewage in the regulating tank is lifted by the pump, and a coagulation mixer is installed on the pipeline behind the pump. The coagulant and coagulant are respectively added before and after the coagulation mixer, and then enters the purifier, and is sorted by the clean coal separation device. The clean coal is discharged and discharged from the equipment, and the clean coal is sieved through a dehydration screen for recycling; the waste water after the clean coal is recovered is centrifuged,

Gravity separation, dynamic check filtration and sludge thickening processes discharge the treated clean water from the top of the purifier and send it to the clean pool.

For reuse or discharge, the concentrated slime discharged from the bottom of the purifier is discharged to the slime percolation and drying tank or dried with drying equipment for use. The slime percolation and drying tank designed by our institute has obvious use effect, which can make the mud water separate quickly and the slime can be quickly dried.

Anionic polyacrylamide is generally used for sewage treatment in coal washing plants, and the main thing we have to determine during use is the amount. Coal has a smaller specific gravity than water. The buoyancy of water is used to separate coal from coal gangue. This process is called coal washing. Coal washing is an industrial process that removes impurities from raw coal, or separates high-quality coal from poor-quality coal.