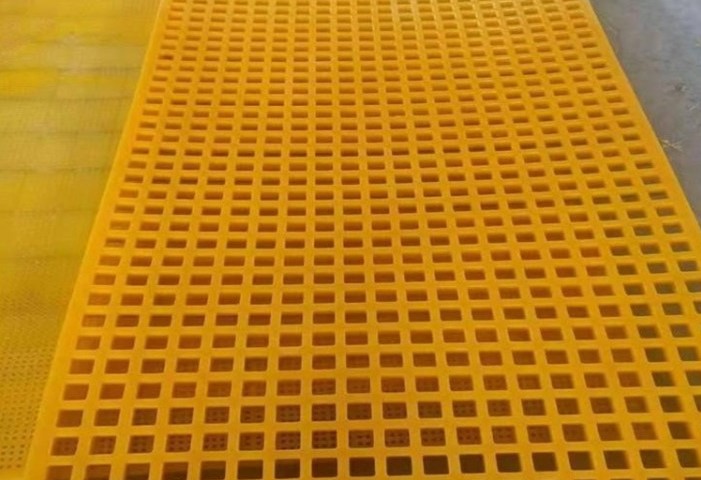

Mine small hole poly screen panel design for India custumers

October.27,2023

October.27,2023

According to the structural form of poly screen plate, it is divided into four types: inlaid type, bolt connection, batten connection and screen hook connection.

Application scope

Vibrating screens are suitable for machinery, petrochemicals, electric power, coal and other industries. They are mainly used for medium and fine-grained screening of bulk materials, and can be used for both dry and wet screening. It can be customized according to the specifications of the Indian vibrating screen.

product details

1. Good shock absorption can reduce noise, so that the materials on the screen plate are not easily damaged during vibration and are not afraid of impacting the screen mesh.

2. Wear resistance: Made of high-quality materials, it is more wear-resistant than ordinary steel screen plates and lasts longer.

3. Smooth surface: Made of polyurethane composite material, the product surface is smooth and clean.

Installation method of poly screen panel

For example, layered connection type: please place the screen plate on the screen surface first, and then install it according to the support beam structure of the screen. Generally, screw holes should be drilled on both sides of the screen machine and on the upper layer of the screen plate along the unloading direction with U-shaped long iron plates of appropriate width at appropriate distances, and then tightened with bolts to the bottom support beam to make the screen plate firmly Fixed in the middle. The contact surfaces between the support beams and the long iron plate and the screen plate are best lined with rubber strips (old hoses can be used). It can also be installed in this way above the support beam in the middle of the screen.

If the screen plate is not installed as required, it may vibrate up and down on the screen surface, causing long-term friction and collision with the steel support beams, which will seriously affect the service life of the screen plate.

Specifications:

(1). The standard type in the table is a commonly used product, and its screening efficiency and service life are moderate; the efficiency type has slightly higher efficiency and slightly lower life; the life type has slightly lower efficiency and longer life.

(2). The sieve hole sizes in the table generally refer to square holes and polyurethane sieve plates. If you need rectangular holes or other hole shapes of different sizes, please contact our company for production.