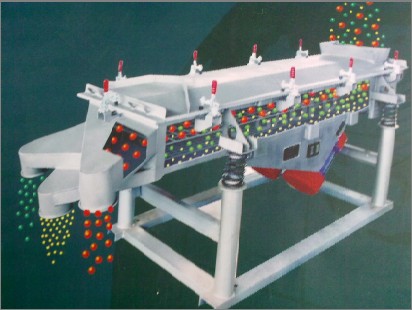

Reasons for the materials deviation of the linear vibrating screen

July.11,2019

July.11,2019

Uneven feeding

If you have read the instructions for the linear vibrating screen in detail, you should know that there is a repeated requirement that is: uniform feeding. Because if the feeding time is too much, it is easy to cause the screening accuracy to be unstable, and the material bias is large due to the material, and the discharge is biased to one side.

Unstable center of gravity

The position of the center of gravity of the linear vibrating screen itself is unstable or the position of the eccentric block of the motor is not balanced.

Component aging

The damper springs and other parts of the screen body are aging and loose. If a certain part has aging problems, it will cause the problem of the deviation of the discharge direction due to the instability of the screen of the linear vibrating screen.

Vibration motor installation problem

It should be noted that as long as the customer is a linear vibrating screen with good design and reasonable consumables purchased by regular manufacturers, the new machine will not have this problem, because the regular manufacturers have professional technicians to carry out precise installation and test machines. Adjust the service to avoid any unexpected situation such as the abnormal operation of the linear vibrating screen due to the deviation of the direction of the exciting force.

Since the wire vibrating screen transports the material by the vibrating motor, the vibrating motor pushes the material with a fixed amount of fixed force in a fixed direction. Therefore, when there is a poor conveying condition, basically It can be judged that there is a problem in the installation angle of the vibration motor.

Screen box deformation

The sieve box refers to a sieve surface which is fixed above the vibration motor and below the feed port and which is fixed by the screen frame and the periphery thereof. Under the normal operation of the linear vibrating screen, especially the large-scale, high-frequency linear vibrating screen, the screen frame needs the strong excitation force of the gravity and vibration motor from the large-scale screening material at the same time. If the strength is not enough, it is easy to be deformed. Damaged problem. The strength of the screen box depends mainly on the manufacturer’s material selection, welding process, and additional robust design.